If you’ve owned a nitro or gas boat for any length of time, it’s highly possible that you’ve had to deal with a non-functioning rope starter on your boat’s engine. Whether the pull cord suddenly snapped or the starter’s internal return spring decided not to retract into the engine’s starter housing, the result is that your day at the lake might be over. Luckily, most all recoil rope starter repairs are doable by the average model boater, plus once you’ve mastered the techniques of servicing an engine rope starter, fixing one at lakeside may be within your grasp.

REMOVAL SAFETY

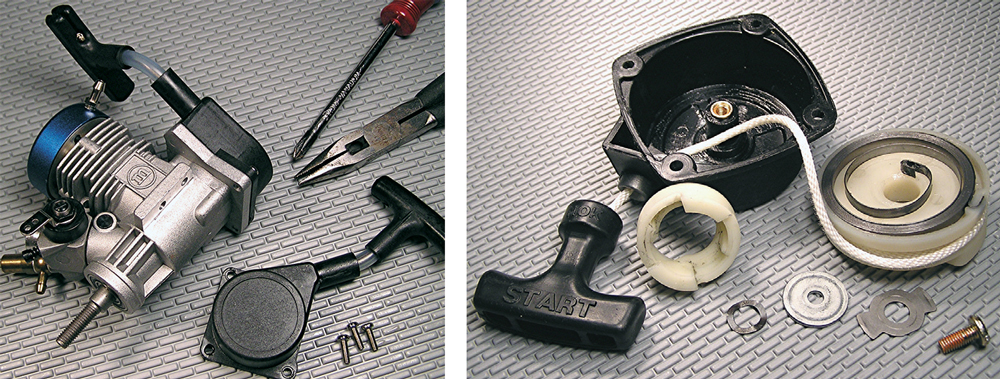

Since all rope starters use a metal coil spring to keep tension on the pull cord, the process of detaching the starter housing for repair must be done carefully to prevent problems. After you’ve unscrewed all of the retaining screws from the starter, removing the case should be done slowly while paying close attention that the spring stays on either the rope drum or the case itself. Once the starter is free of the engine and on your workbench, the next step will be to clean and inspect the entire unit as this will make it easier to work on it safely and help you clearly determine what’s wrong inside the starter.

THE LIKELY SUSPECTS

In general, the three main repair points on a nitro or gas engine starter will be a snapped pull rope, a broken return spring or a malfunction in the unit’s engagement ratchet setup. On a broken spring or pull rope, the starter might require a complete disassembly. As you remove the parts, you can document their locations on paper or via the camera on your cell phone. After uncovering the return spring’s location (either in the case or on the rope drum) you can check it and the pull rope’s condition and then make up your parts list to complete the rebuild. Overall, it’s best to replace the spring and the pull cord at the same time if you see any signs of rope wear or spring tension loss, especially if you run your boat on a regular basis.

PARTS SOURCES

When servicing an RTR nitro boat rope starter, you should be able to obtain a pull rope or any drum and ratchet components found inside the starter housing from the hull’s manufacturer. If you are unable to find a new rope for your particular engine, such companies as Team Associated and others sell suitable replacement pull ropes for nitro marine engine usage as the engines in many RC cars have the same type of rope starters. On a Zenoah gasoline engine starter components can come from Horizon Hobby, Warehouse Hobbies and other sources, plus it’s possible to get proper pull rope from any good lawnmower shop that services yard tools. Above all else you’ll greatly benefit from always carefully matching your new pull starter parts to insure there will be no hassles when you’re reassembling the rope starter.

SPRING AND ROPE TRICKS

Due to their relatively small size and the level of stored energy in their tensioned form, a boat’s rope return spring installation will have to be done with a good pair of needle-nose pliers. Once you’re sure that the spring rotation matches the starter drum or housing’s mounting location, installing the spring will only involve placing it with its outer hook in its retaining slot and then slowly allowing the coils to expand into the proper location. You might have to slightly tweak the spring’s inner hook to leave enough space for the drum or housing’s retaining slot and here again this chore is best done with those needlenose pliers.

The installed return spring should sit flat and adding a slight amount of grease on the spring will help it operate smoothly once the starter is back together.

For the replacement of a broken pull rope, you’ll need to first size the new cord’s length to the snapped rope and then route the fresh cord through the pull handle, starter housing opening and the round rope drum’s rope hole. On those rope drums that place the new rope end on the underside of the drum (facing the return spring) a simple overhand knot should be put in the rope end followed by a light melting of the knot’s remaining cord end with a suitable heat source. Once situated in the drum’s cord end recess, the opposite end of the rope (at the pull handle) can be given a loose loop knot for the time being. To actually add tension to the spring and rope, a small loop of the new cord is now made inside the starter housing and you should end up with the loop situated in the rope drum’s outer notch. With your cord loop made, you can slowly install the drum into the housing taking, extra care not to force anything into place as this could dislodge the tension spring from its mounting spot.

At this juncture the cord itself can be used to reestablish tension on it and the return spring via that small loop you made in the rope. This loop acts as a holding point to slowly spin the rope drum counter-clockwise, adding the tension to the starter. You’ll need to hold the drum down tight with your other hand as this will prevent it from rising up and keep the spring inside the housing. After adding a couple of full rotations of the drum, you can allow the rope loop to pass out of the housing’s rope opening and you can check to see if the cord fully retracts into the starter unit. If more tension is needed you can simply redo the loop in the rope and add another full turn to the drum. Once you’re satisfied with the return spring/rope tension, you can create your retaining knot on the pull start handle’s outer rope end and use either heat or a drop of CA glue to lock the knot in place.

ENGAGEMENT WOES

For those times when your boat’s rope starter won’t catch or turnover the engine, there are certain things you can quickly check to remedy the problem. On nitro starters, the main source of engagement glitches center on the one-way bearing that fits both the crankshaft end and into the hex-shaped opening in the starter’s rope drum.

It only takes a small bit of debris or a drop or two of water to cause the bearing to not “catch” properly, however you can sometimes save the bearing by giving it a simple motor cleaner and WD-40 cleaning to return its ratcheting action to normal. Should this trick not work, replacing the bearing assembly will be necessary to provide a constant tension between the recoil rope and the engine.

On gas hull engines, the starter ratchet is usually located on the rope drum which in turn is equipped with a return spring or a simple ratchet setup to activate the starter as you pull the rope. To check its function, you must detach the starter unit and while watching the ratchet location, slowly pull the rope. The ratchet should either extend up or out of the drum to engage the engine’s crankshaft-mounted arbor plate and once you release tension on the rope it must retract properly to the drum body. In most cases the non-engagement on these ratchets are caused by high wear on their nylon or plastic tips and will demand their replacement to cure the problem. Again, cleaning the area before you check or remove the ratchet is a good idea to be sure you’re curing the problem. With the new parts in place, you can recheck the starter’s action as you pull the cord and if everything’s working right you can reinstall the recoil rope housing onto the engine.

PRO TIPS

• Once you begin to see any wear on the pull rope, replacing it will prevent a sudden cord failure or a damaged return spring when the broken rope allows the drum to over-rotate inside the starter housing.

• In the event your boat takes on a lot of water, remove the starter and make sure no moisture remains inside the housing and its components.

• Before you head to the lake, give the hull’s starter rope a couple of pulls to insure the ratchet is working correctly.

• For the racer, the idea of having a spare, complete rope starter assembly or just a backup rope and handle setup in your toolbox can make the difference between making the start of the next heat race and scoring a DNS.

• To ease routing of a new rope through the starter components, either melt the end or “freeze” it with CA glue to avoid having the cord end fray as it contacts the starter parts.

WRAP-UP

Having the knowledge to easily troubleshoot and cure a stubborn rope starter gives you the ability to quickly save your valuable time at the lake. The only downside to learning how to mend a broken rope and or spring on your boat is that eventually, the rest of your friends will want you to fix their powerboats’ rope starters!

LINKS

Horizon Hobby horizonhobby.com, 800-338-4639

Team Associated teamassociated.com, 949-544-7500

Warehouse Hobbies whobbies.com, 863-699-1231

RC Boat Magazine The World's Leading Radio Control Boating Magazine

RC Boat Magazine The World's Leading Radio Control Boating Magazine